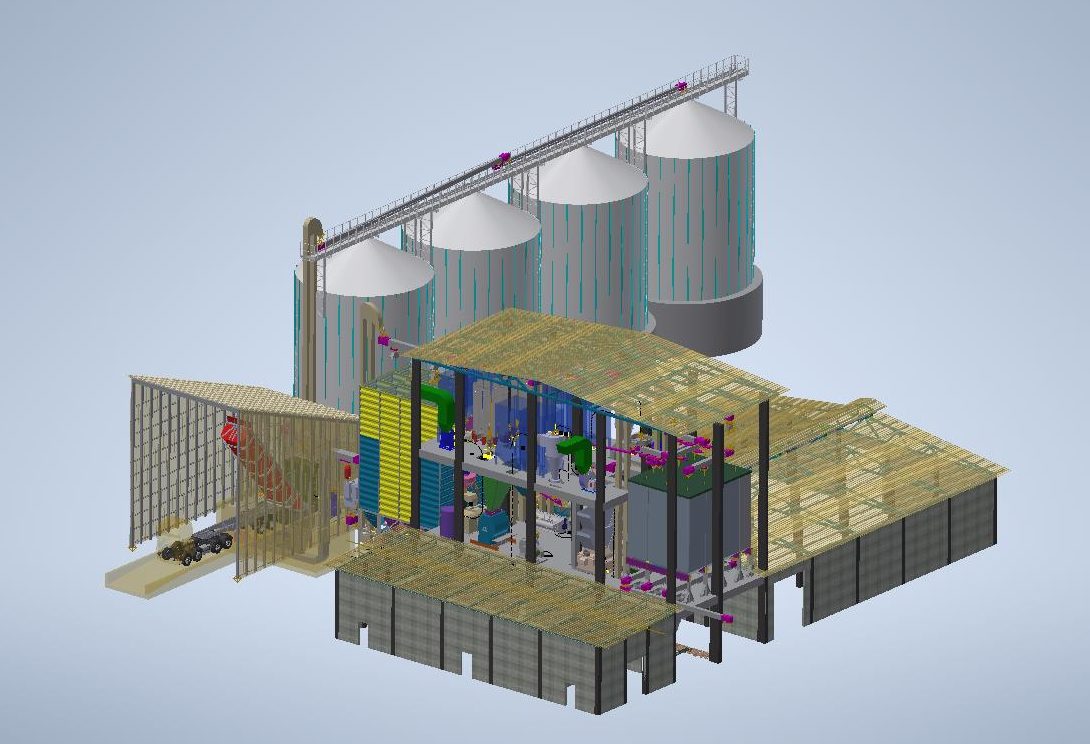

Planning / Layout

- Layout planning and budgeting at the very start of each new project

- Building permit documents, foundation design

- Function and process descriptions

- 3D scanning

- Product development of customer products

- Project management

Mechanical desing

- We use Inventor and Tekla

- Sheet metal design

- Machine and equipment design

- Structural design according to EN 1090 standards

- Documentation

- Product development

- Strength calculation

Electrical automation design

- Electrical and automation design for a wide range of industries.

- We also supply total deliveries of electrification, automation, and logic renewal and renovation projects.

- Our automation designers are experts in programming process control systems and logics. We mainly use Beckhoff and Siemens.

• Project planning

• Electrical design

• Automation design

• Instrumentation design

• Project management

• Installation supervision

• Preventive maintenance and spare parts reports

Industrial maintenance

We understand that safe and continuously operating production equipment is vital for the profitability of our customers’ business operations. Regular maintenance achieves a longer service life for investments and maximises production efficiency. We like to learn about our customers' production processes in depth so that we can serve them even better in the future. We are able to react quickly to problem situations and serve you flexibly with a package tailored to your needs. Sticking to schedules is the basis of our operations.

- Predictive maintenance

- Long-term maintenance agreements

- Short-term maintenance work

- Our extensive expertise allows us to offer not only mechanical maintenance but also maintenance work that requires electrical and automation expertise.

- Enhanced production and operational reliability

- Maintenance programs + documentation

Engineering workshop

Our engineering workshop mainly manufactures equipment that we have designed ourselves, but also equipment and steel structures as a subcontractor according to the customer’s designs. In addition to machinery and equipment, we also manufacture steel structures for project deliveries. Our workshop has the EN 1090 quality system for steel structures.

The equipment we manufacture is mainly used in the feed, grain and process industries, but also in other industries. Our workshop has equipment for the sawing, plasma cutting, edging and machining of beams. We use MIG, MAG, TIG and stick welding equipment that is operated by sheet metal welders with years of experience. In addition, our operations are supported by an extensive subcontracting network. Our material inventory includes carbon steel, stainless steel, acid-resistant steel, abrasion resistant steel and duplex steel.

Our workshop operations also support our maintenance operations by stocking standard products and responding quickly in the event of a problem. In addition, we also stock the machines and equipment of our partner company.

Machine and equipment installations

We provide machine and equipment installations for several different industries. All of our machine and equipment installations are performed safely, from planning to commissioning, and our maintenance department also takes care of maintenance in the future. Our versatile expertise enables us to handle even complex projects, from small equipment installations to entire factories. We have implemented many successful projects for different industries according to agreed schedules.

- Turnkey deliveries

- Partial and total projects

- Support for the customer's own personnel

- Installation supervision

- General maintenance

Electrical and automation installations

Our special expertise is electrical and instrument installations for new industrial automation systems and modernisations of existing systems. We deliver industrial electrical and automation installations quickly and reliably. With the help of an extensive and competent network of partners, we even handle larger automation projects, such as process and production control systems and modernisations of control systems. Automation systems are always implemented in close cooperation with the customer.

• Electrical contracting

• Electrical and automation installations

• Instrumentation

• Total industrial projects

• Electrical and automation maintenance of production machinery

• Contract-based maintenance services

• Electrical and automation maintenance of production machinery

• Modernisations of production machinery and lines

• Measurements, mass flow measurements, temperature, scales

• S2 contracting rights

• Installation supervision

• Thermal imaging

• Inspections of scales and other measuring equipment